What is Roller-Compacted Concrete (RCC)?

Roller-Compacted Concrete (RCC) is a specialized type of concrete produced by mixing aggregate with a controlled amount of water and cement at a ready-mix concrete plant. Due to its lower water content compared to traditional concrete, RCC has a water/cement ratio that can decrease to around 0.30. Additionally, RCC has up to four times fewer voids due to its compaction to 98% of its dry unit weight, resulting in a 70-80% increase in compressive strength at 28 days compared to conventional concrete with the same cement dosage.

RCC pavements combine the high strength and durability of concrete with the construction speed and early traffic opening benefits of flexible pavements.

Produced at ready-mix concrete plants, RCC is transported in dump trucks due to its dry consistency and is laid and compacted using road construction equipment.

RCC offers up to 70-80% higher compressive strength than traditional concrete with the same cement dosage.

History of Roller-Compacted Concrete

The roller-compacted concrete technique was first used in 1940 at Washington Airport in the United States. It later spread to Canada and European countries, and has since become widespread globally.

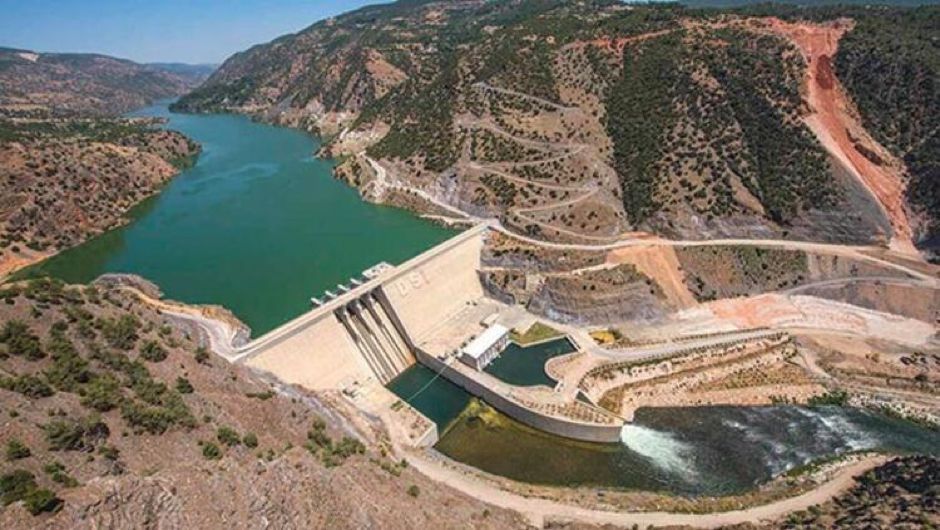

In Turkey, the first applications of RCC began with dam constructions. Turkey hosts Europe’s tallest RCC dams, including the Çetin Dam in Siirt, which stands at 165 meters high.

Applications of Roller-Compacted Concrete

- Rural and urban roads

- Industrial facilities

- Ports

- Parks and storage areas

- Intermodal transport areas and loading docks

- Distribution centers

- Aircraft parking areas

- Military bases, forward and rear operations areas, airfields

- Large commercial parking lots

- Lumber and timber mill areas and internal roads

- Highways

Advantages of Roller-Compacted Concrete

- Long Service Life: RCC can last up to 25 years, offering 3-4 times the service life of alternatives.

- Low Maintenance: It requires very little maintenance and repair over its long service life.

- Quick Traffic Opening: RCC surfaces can be opened to traffic within 24-36 hours.

- Reduced Shrinkage: The low mix content reduces shrinkage and minimizes shrinkage-induced cracking.

- High Strength: RCC can be designed to withstand high bending, compressive, and shear stresses, making it suitable for heavy industries, mining, and military applications.

- Excellent Freeze-Thaw Resistance: RCC has a low void ratio and independent voids, providing high freeze-thaw resistance. It has demonstrated excellent freeze-thaw durability in cold regions in Canada and North America for decades.

- Chemical Resistance: RCC’s low permeability gives it resistance to chemical effects and outstanding durability.

- No Rutting: RCC pavements do not exhibit wheel rutting.

- Wear Resistance: RCC is resistant to abrasion even under heavy loads and high traffic volumes.

- Reduced Lighting Needs: The light color of RCC surfaces reduces lighting requirements for parking lots and storage areas.

- Thick Layers: RCC can be constructed in thicknesses up to 35 cm with high-density finishers.

- High Solar Reflectance Index (SRI): RCC surfaces exceed the minimum SRI score of 29 required for Energy and Environmental Design Leadership (LEED) Credit 7.1: "Heat Island Effect."

RCC continues to be a durable and practical solution for various applications worldwide, offering a combination of high performance, cost-effectiveness, and sustainability.